In today’s fast-paced world, cardboard food boxes have become an essential item for food businesses. These custom chocolate boxes not only ensure the safety of the food during transportation but also act as a branding tool. Custom takeaway food boxes and packaging can help businesses to stand out in a crowded market. In this blog, we will discuss the benefits of using custom food boxes, printing techniques, colour models, add-ons, finishing coats, prototypes, and a sales pitch for your business. Whether you’re a small business owner or a large corporation, this blog will provide valuable information about printed cardboard food boxes UK.

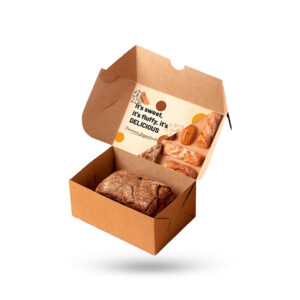

Customised food packaging is a game-changer for food businesses. With customised packaging, you can showcase your brand’s unique identity and differentiate yourself from your competitors. Your brownie packaging should be designed to match your brand’s colours, font, and logo. Customised Barbie popcorn boxes can also be designed with your target audience in mind, catering to their preferences and needs. Whether you’re a small business or a large corporation, food packaging can help elevate your brand and increase your customer base.

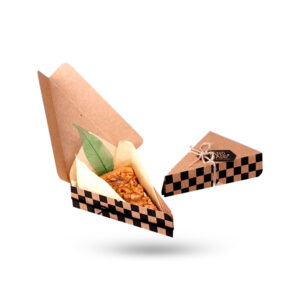

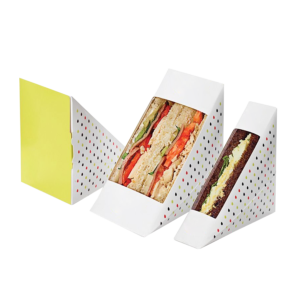

Custom sandwich sleeve packaging can provide several benefits for your business. Firstly, it ensures the safety of your food during transportation. Secondly, it acts as a branding tool that can help you stand out in a crowded market. Burger Boxes packaging can be designed to feature your business’s logo, tagline, and other branding elements. This helps to increase brand awareness and recognition. Lastly, Brown food packaging UK can be used to promote your business’s sustainability efforts by using eco-friendly materials and printing techniques.

Printing techniques are essential in customising your printed wholesales food boxes. Flexography, digital printing, lithography, and screen printing are popular techniques used in printing on wholesale macaron boxes. Each technique has its benefits and drawbacks. Flexography is popular for printing on corrugated cardboard. Digital printing is ideal for small print runs and can be cost-effective. Lithography produces sharp images and is ideal for high-quality printing. Screen printing is perfect for printing on uneven surfaces.

There are two main colour models used in printing: RGB and CMYK. RGB is used for digital displays, while CMYK is used for print. CMYK produces accurate colours and is ideal for printing on food packaging popcorn boxes.

Add-ons can be used to enhance the design of your Custom food boxes with window. Embossing, debossing, foil stamping, and spot UV coating are popular addons. Embossing and debossing create a raised or recessed image on the cookies boxes. Foil stamping adds a metallic finish to the design, while spot UV coating adds a glossy finish to specific areas of the box.

Finishing coats can be applied to self lock cake boxes are best for cake industry for presenting. Buy food boxes UK to protect them from moisture and other environmental factors. Aqueous coating, varnish, and lamination are popular finishing coats used in food packaging. Aqueous coating is a water-based coating that provides a matte or gloss finish and is eco-friendly. Varnish is an oil-based coating that adds a glossy finish and provides additional protection against scratches and scuffs. Lamination involves applying a thin film over the food box, which provides an extra layer of protection against moisture and other environmental factors.

The Importance of Prototypes in Custom Food Box Design

Prototyping is an essential step in designing custom Kraft food boxes. Prototypes allow you to see and test the design before finalizing it. This can help you identify any design flaws and make adjustments before production. Prototyping also allows you to see how the design will look and feel in person, which can help you make informed decisions about materials, printing techniques, and add-ons.

How to Pitch Your Custom Food Boxes to Potential Customers

Once you have designed your custom tea boxes, it’s time to pitch them to potential customers. It’s important to highlight the unique features of your packaging, such as your branding elements, materials, and add-ons. You should also emphasize the benefits of using cardboard food delivery boxes, such as increased safety during transportation, brand recognition, and sustainability efforts. Consider offering samples or a trial run to potential customers to demonstrate the quality of your packaging.

Transform Your Food Packaging with Custom Food Box Packaging

Custom cupcake boxes packaging can transform your food packaging and take your business to the next level. By using customized packaging, you can showcase your brand’s unique identity, increase brand recognition, and stand out in a crowded market. With the right printing techniques, colour models, add-ons, finishing coats, and prototypes, you can design custom premium food boxes that meet the specific needs of your business and appeal to your target audience. Custom food box packaging is an investment in your brand’s future and can help you achieve long-term success.

In today’s fast-paced world, cardboard food boxes have become an essential item for food businesses. These custom chocolate boxes not only ensure the safety of the food during transportation but also act as a branding tool. Custom takeaway food boxes and packaging can help businesses to stand out in a crowded market. In this blog, we will discuss the benefits of using custom food boxes, printing techniques, colour models, add-ons, finishing coats, prototypes, and a sales pitch for your business. Whether you’re a small business owner or a large corporation, this blog will provide valuable information about printed cardboard food boxes UK. Stand Out from the Crowd with Customised Food Packaging Customised food packaging is a game-changer for food businesses. With customised packaging, you can showcase your brand’s unique identity and differentiate yourself from your competitors. Your brownie packaging should be designed to match your brand’s colours, font, and logo. Customised Barbie popcorn boxes can also be designed with your target audience in mind, catering to their preferences and needs. Whether you’re a small business or a large corporation, food packaging can help elevate your brand and increase your customer base. The Benefits of Custom Food Packaging for Your Brand Custom sandwich sleeve packaging can provide several benefits…

In today’s fast-paced world, cardboard food boxes have become an essential item for food businesses. These custom chocolate boxes not only ensure the safety of the food during transportation but also act as a branding tool. Custom takeaway food boxes and packaging can help businesses to stand out in a crowded market. In this blog, we will discuss the benefits of using custom food boxes, printing techniques, colour models, add-ons, finishing coats, prototypes, and a sales pitch for your business. Whether you’re a small business owner or a large corporation, this blog will provide valuable information about printed cardboard food boxes UK.

Customised food packaging is a game-changer for food businesses. With customised packaging, you can showcase your brand’s unique identity and differentiate yourself from your competitors. Your brownie packaging should be designed to match your brand’s colours, font, and logo. Customised Barbie popcorn boxes can also be designed with your target audience in mind, catering to their preferences and needs. Whether you’re a small business or a large corporation, food packaging can help elevate your brand and increase your customer base.

Custom sandwich sleeve packaging can provide several benefits for your business. Firstly, it ensures the safety of your food during transportation. Secondly, it acts as a branding tool that can help you stand out in a crowded market. Burger Boxes packaging can be designed to feature your business’s logo, tagline, and other branding elements. This helps to increase brand awareness and recognition. Lastly, Brown food packaging UK can be used to promote your business’s sustainability efforts by using eco-friendly materials and printing techniques.

Printing techniques are essential in customising your printed wholesales food boxes. Flexography, digital printing, lithography, and screen printing are popular techniques used in printing on wholesale macaron boxes. Each technique has its benefits and drawbacks. Flexography is popular for printing on corrugated cardboard. Digital printing is ideal for small print runs and can be cost-effective. Lithography produces sharp images and is ideal for high-quality printing. Screen printing is perfect for printing on uneven surfaces.

There are two main colour models used in printing: RGB and CMYK. RGB is used for digital displays, while CMYK is used for print. CMYK produces accurate colours and is ideal for printing on food packaging popcorn boxes.

Add-ons can be used to enhance the design of your Custom food boxes with window. Embossing, debossing, foil stamping, and spot UV coating are popular addons. Embossing and debossing create a raised or recessed image on the cookies boxes. Foil stamping adds a metallic finish to the design, while spot UV coating adds a glossy finish to specific areas of the box.

Finishing coats can be applied to self lock cake boxes are best for cake industry for presenting. Buy food boxes UK to protect them from moisture and other environmental factors. Aqueous coating, varnish, and lamination are popular finishing coats used in food packaging. Aqueous coating is a water-based coating that provides a matte or gloss finish and is eco-friendly. Varnish is an oil-based coating that adds a glossy finish and provides additional protection against scratches and scuffs. Lamination involves applying a thin film over the food box, which provides an extra layer of protection against moisture and other environmental factors.

The Importance of Prototypes in Custom Food Box Design

Prototyping is an essential step in designing custom Kraft food boxes. Prototypes allow you to see and test the design before finalizing it. This can help you identify any design flaws and make adjustments before production. Prototyping also allows you to see how the design will look and feel in person, which can help you make informed decisions about materials, printing techniques, and add-ons.

How to Pitch Your Custom Food Boxes to Potential Customers

Once you have designed your custom tea boxes, it’s time to pitch them to potential customers. It’s important to highlight the unique features of your packaging, such as your branding elements, materials, and add-ons. You should also emphasize the benefits of using cardboard food delivery boxes, such as increased safety during transportation, brand recognition, and sustainability efforts. Consider offering samples or a trial run to potential customers to demonstrate the quality of your packaging.

Transform Your Food Packaging with Custom Food Box Packaging

Custom cupcake boxes packaging can transform your food packaging and take your business to the next level. By using customized packaging, you can showcase your brand’s unique identity, increase brand recognition, and stand out in a crowded market. With the right printing techniques, colour models, add-ons, finishing coats, and prototypes, you can design custom premium food boxes that meet the specific needs of your business and appeal to your target audience. Custom food box packaging is an investment in your brand’s future and can help you achieve long-term success.