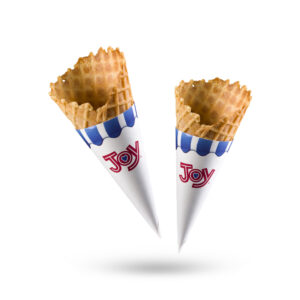

Cone sleeves are a popular type of packaging used to enhance the presentation and protection of ice cream cones, waffle cones, and other confectionery items. Custom Printed Cone Sleeves are designed to fit snugly around the cone, providing a barrier between the ice cream and the cone to prevent leaks and drips. Cone sleeves are typically made from sturdy paper materials that are food-safe and environmentally friendly, making them a great choice for businesses looking to reduce their environmental impact.

In addition to their practical benefits, branded ice cream cone sleeves also offer a great opportunity for branding and customization, with many businesses choosing to add their logo or other designs to the ice cream paper cone sleeves to promote their brand and create a more memorable customer experience. Overall, kraft cone sleeves are a versatile and useful packaging solution that can help businesses elevate their ice cream and confectionery offerings while also enhancing their brand image.

Custom Crepe Cone Packaging typically consists of paper or cardboard materials that are food-safe and environmentally friendly. Cone sleeves are perfect to provide a barrier between the ice cream or other confectionery items and the cone itself. This thing eventually helps to prevent leaks and drips and keep the customer’s hands clean. They also serve to enhance the presentation of the product, making it more visually appealing to the customer.

personalizes Ice cream cone sleeves is a favourite treat for many people, but it can be messy to eat, especially when served in a cone. This is where a custom nut paper Cone comes in handy. Cone sleeves are paper or cardboard sleeves that fit over ice cream cones, providing a barrier between the ice cream and the cone, making it less messy to eat. In this article, we will discuss the benefits of sleeve cones.

Less mess:

One of the biggest benefits of using custom Printed french fries Cone Sleeve is that they help to reduce messiness. Without a cone sleeve, ice cream can drip and melt, causing sticky fingers and making a mess. However, with a cone sleeve, the ice cream is contained within the sleeve, reducing the chances of spills and drips.

Increased comfort:

Holding an ice cream cone wrapper for an extended period can be uncomfortable, especially on hot summer days. Plain Cone Sleeves provide a layer of insulation, making it more comfortable to hold the cone. Additionally, cone sleeves prevent the ice cream from freezing on the hands, making it easier to enjoy the treat.

Branding opportunities:

Waffle Cone sleeves provide an excellent opportunity for branding and marketing. Businesses can customize the cone sleeves with their logos and designs, making it easier to promote their brand and create a more memorable customer experience. Customized cone sleeves are a cost-effective way to increase brand awareness and stand out from the competition.

Environmentally friendly: Cone sleeves are typically made from paper or cardboard, making them a more environmentally friendly option than plastic packaging. They are also biodegradable and recyclable, making them a more sustainable choice.

Versatile:

Cone sleeves manufacture in UK are versatile and can be used with a variety of ice cream cones, including waffle cones, sugar cones, and cake cones. They can also be used with other confectionery items, such as churros or doughnuts, making them a practical option for many businesses.

Ice cream cone holder offer many benefits for businesses and customers alike. They provide a practical solution for reducing messiness and increasing comfort while also offering branding opportunities and being environmentally friendly. With their versatility and affordability, cone sleeves are a packaging option that many businesses should consider when serving ice cream and other confectionery items.

Several finishing coatings can be used on snacks paper cone reflective sleeve to enhance their appearance and durability.

Gloss coating:

Gloss coating is a shiny, reflective coating that gives the pizza cone packaging a glossy finish. It is a popular choice for cone sleeves as it makes the colours appear brighter and more vibrant.

Matte coating:

Matte coating is a non-glossy coating that gives the popcorn paper cone a soft, velvety finish. It is a great choice for a more subtle, sophisticated look.

Spot UV coating:

Spot UV coating is a technique where only certain areas of the wholesales ice cream cone sleeve are coated with a glossy finish.

Soft-touch coating:

The soft-touch coating is a coating that gives the cone sleeve a soft, rubbery texture. It is a great option for creating a tactile experience for the customer.

Looking for a practical and stylish way to package your delicious ice cream treats? Look no further than packaging bull! Our branded custom ice cream cone sleeves include gloss, matte, spot UV, and soft touch. Plus, they offer a great opportunity to promote your brand with customizable designs and branding options. Whether you’re serving waffle cones, sugar cones, or cake cones, our cone sleeves as well custom ice cream Tubs Packaging are a great way to make your treats more enjoyable and memorable for your customers. Don’t settle for messy and boring packaging upgrade to our ice cream cone sleeves UK today!

Why cone sleeves are the way to go Cone sleeves are a popular type of packaging used to enhance the presentation and protection of ice cream cones, waffle cones, and other confectionery items. Custom Printed Cone Sleeves are designed to fit snugly around the cone, providing a barrier between the ice cream and the cone to prevent leaks and drips. Cone sleeves are typically made from sturdy paper materials that are food-safe and environmentally friendly, making them a great choice for businesses looking to reduce their environmental impact. In addition to their practical benefits, branded ice cream cone sleeves also offer a great opportunity for branding and customization, with many businesses choosing to add their logo or other designs to the ice cream paper cone sleeves to promote their brand and create a more memorable customer experience. Overall, kraft cone sleeves are a versatile and useful packaging solution that can help businesses elevate their ice cream and confectionery offerings while also enhancing their brand image. What are cone sleeves? Custom Crepe Cone Packaging typically consists of paper or cardboard materials that are food-safe and environmentally friendly. Cone sleeves are perfect to provide a barrier between the ice cream or other confectionery items and the cone…

Cone sleeves are a popular type of packaging used to enhance the presentation and protection of ice cream cones, waffle cones, and other confectionery items. Custom Printed Cone Sleeves are designed to fit snugly around the cone, providing a barrier between the ice cream and the cone to prevent leaks and drips. Cone sleeves are typically made from sturdy paper materials that are food-safe and environmentally friendly, making them a great choice for businesses looking to reduce their environmental impact.

In addition to their practical benefits, branded ice cream cone sleeves also offer a great opportunity for branding and customization, with many businesses choosing to add their logo or other designs to the ice cream paper cone sleeves to promote their brand and create a more memorable customer experience. Overall, kraft cone sleeves are a versatile and useful packaging solution that can help businesses elevate their ice cream and confectionery offerings while also enhancing their brand image.

Custom Crepe Cone Packaging typically consists of paper or cardboard materials that are food-safe and environmentally friendly. Cone sleeves are perfect to provide a barrier between the ice cream or other confectionery items and the cone itself. This thing eventually helps to prevent leaks and drips and keep the customer’s hands clean. They also serve to enhance the presentation of the product, making it more visually appealing to the customer.

personalizes Ice cream cone sleeves is a favourite treat for many people, but it can be messy to eat, especially when served in a cone. This is where a custom nut paper Cone comes in handy. Cone sleeves are paper or cardboard sleeves that fit over ice cream cones, providing a barrier between the ice cream and the cone, making it less messy to eat. In this article, we will discuss the benefits of sleeve cones.

Less mess:

One of the biggest benefits of using custom Printed french fries Cone Sleeve is that they help to reduce messiness. Without a cone sleeve, ice cream can drip and melt, causing sticky fingers and making a mess. However, with a cone sleeve, the ice cream is contained within the sleeve, reducing the chances of spills and drips.

Increased comfort:

Holding an ice cream cone wrapper for an extended period can be uncomfortable, especially on hot summer days. Plain Cone Sleeves provide a layer of insulation, making it more comfortable to hold the cone. Additionally, cone sleeves prevent the ice cream from freezing on the hands, making it easier to enjoy the treat.

Branding opportunities:

Waffle Cone sleeves provide an excellent opportunity for branding and marketing. Businesses can customize the cone sleeves with their logos and designs, making it easier to promote their brand and create a more memorable customer experience. Customized cone sleeves are a cost-effective way to increase brand awareness and stand out from the competition.

Environmentally friendly: Cone sleeves are typically made from paper or cardboard, making them a more environmentally friendly option than plastic packaging. They are also biodegradable and recyclable, making them a more sustainable choice.

Versatile:

Cone sleeves manufacture in UK are versatile and can be used with a variety of ice cream cones, including waffle cones, sugar cones, and cake cones. They can also be used with other confectionery items, such as churros or doughnuts, making them a practical option for many businesses.

Ice cream cone holder offer many benefits for businesses and customers alike. They provide a practical solution for reducing messiness and increasing comfort while also offering branding opportunities and being environmentally friendly. With their versatility and affordability, cone sleeves are a packaging option that many businesses should consider when serving ice cream and other confectionery items.

Several finishing coatings can be used on snacks paper cone reflective sleeve to enhance their appearance and durability.

Gloss coating:

Gloss coating is a shiny, reflective coating that gives the pizza cone packaging a glossy finish. It is a popular choice for cone sleeves as it makes the colours appear brighter and more vibrant.

Matte coating:

Matte coating is a non-glossy coating that gives the popcorn paper cone a soft, velvety finish. It is a great choice for a more subtle, sophisticated look.

Spot UV coating:

Spot UV coating is a technique where only certain areas of the wholesales ice cream cone sleeve are coated with a glossy finish.

Soft-touch coating:

The soft-touch coating is a coating that gives the cone sleeve a soft, rubbery texture. It is a great option for creating a tactile experience for the customer.

Looking for a practical and stylish way to package your delicious ice cream treats? Look no further than packaging bull! Our branded custom ice cream cone sleeves include gloss, matte, spot UV, and soft touch. Plus, they offer a great opportunity to promote your brand with customizable designs and branding options. Whether you’re serving waffle cones, sugar cones, or cake cones, our cone sleeves as well custom ice cream Tubs Packaging are a great way to make your treats more enjoyable and memorable for your customers. Don’t settle for messy and boring packaging upgrade to our ice cream cone sleeves UK today!