Be the first to review “Food Packaging Sleeves” Cancel reply

Packaging Bull takes pride in being your trusted partner in the world of food packaging. Our dedication to quality extends beyond just the products we offer – it’s about the entire experience. From the moment you place your order to the delivery of your custom food Packaging sleeves, we’re committed to ensuring your satisfaction every step of the way.

But don’t just take our word for it – join the countless businesses that have already experienced the difference with Packaging Bull’s food packaging sleeve. Whether you’re looking to streamline your operations, enhance your brand image, or simply elevate your customer experience, our print soap sleeve packaging are the perfect solution.

Order your custom food sleeves from Packaging Bull today and discover why we’re the preferred choice for businesses across the UK. With our attention to detail, commitment to quality, and dedication to customer satisfaction, you can trust us to deliver packaging solutions that not only meet but exceed your expectations

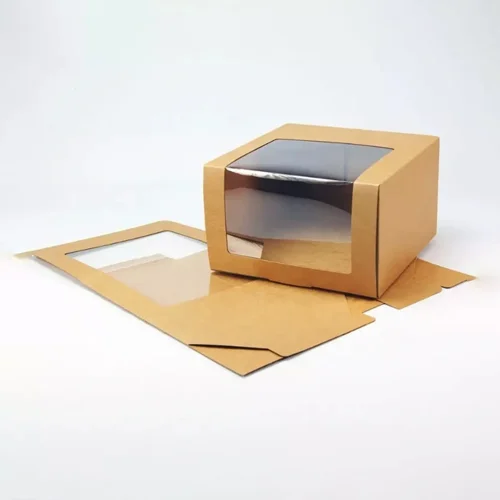

| Box Style | Custom Food Packaging Sleeves |

| Dimension (L + W + H) | All Custom Sizes & Shapes |

| Quantities | No Minimum Order Required |

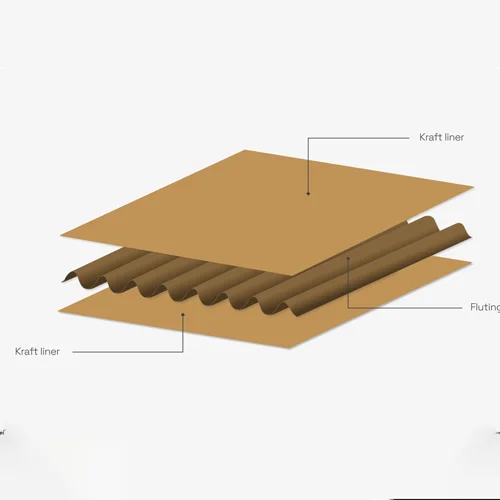

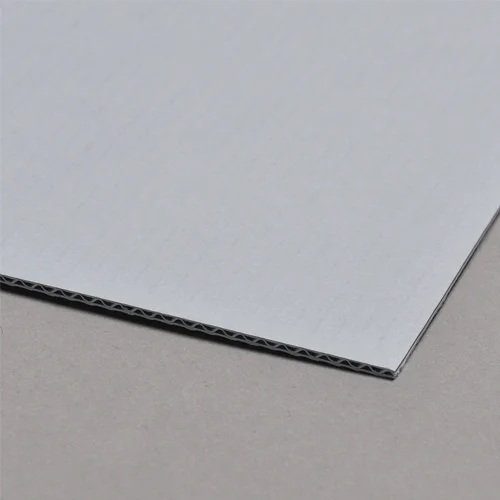

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Printing | No Printing, CMYK, CMYK + 1 PMS color, CMYK + 2 PMS colors |

| Finishing | Gloss Lamination, Matte Lamination, Gloss AQ, Gloss UV, Matte UV |

| Included Options | Die Cutting, Gluing, Scored, Perforation |

| Additional Options | Custom Die Cut, PVC Window, Debossing, Spot UV, Embossing, Foiling |

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) |

| Turnaround | 4 – 8 Business Days, RUSH |

| Shipping | FLAT |

Free Design Support

Free Custom Box Dieline

Free Shipping

Reviews

There are no reviews yet.